Contract Manufacturing and OEM Supply

KENEI Pharmaceutical’s

Contract Manufacturing and OEM SupplyContract Manufacturing &

OEM Services by Ken-ei Pharmaceutical

At KENEI Pharmaceutical, all employees work together to comply with GMP※standards, ensuring rigorous manufacturing and quality control.

We are committed to delivering safe and reliable products that meet these standards to our customers and patients.

We actively engage not only in OEM※but also in ODM※, but also in ODM*, leveraging our experience as a developer of a wide range of products, including those for the pharmaceutical and cosmetics industries. Leveraging the extensive experience and proven track record we have built through contract manufacturing for numerous pharmaceutical companies, we offer tailored proposals to meet a wide range of needs.

※GMP (Good Manufacturing Practice): Standards for manufacturing and quality control in pharmaceutical production

※OEM (Original Equipment Manufacturing): A form of contract manufacturing in which the contractor produces products based on the client’s design and development

※ODM (Original Design Manufacturing): A form of contract manufacturing in which the contractor handles the entire process from planning and design to development and production

Liquid formulations

- ・We are capable of manufacturing a wide range of products, from pharmaceuticals to food additives, with a focus on alcohol-based disinfectants. Our products meet the diverse needs of medical institutions, educational facilities, offices, and households.

- ・We offer comprehensive support from planning to mass production (ODM), with capabilities ranging from small-lot to large-scale manufacturing.

![]()

Powder formulations

- ・Raw material weighing, granulation, drying, and mixing are all performed in environments with controlled cleanliness levels.

- ・We can accommodate a wide range of packaging formats, from unit-dose packages to bulk containers.

- ・Our proprietary technologies enable the development of formulations that are easy to take.

![]()

Semi-solid formulations

- ・We quickly manufacture high-quality formulations such as ointments, creams, and gels.

- ・We support a wide variety of packaging formats and provide one-stop services from planning and manufacturing to filling and packaging.

- ・We flexibly accommodate everything from small-lot to large-scale production.

![]()

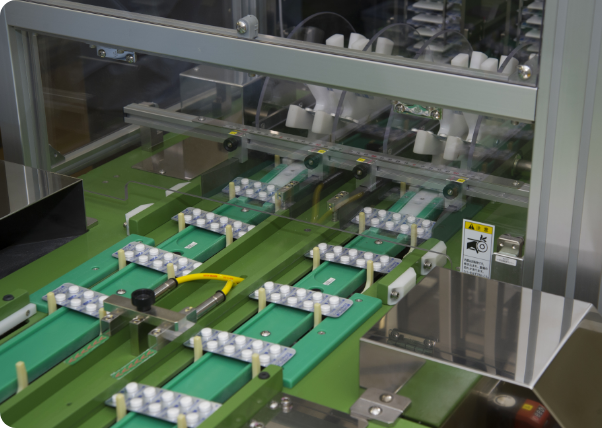

Solid formulations

- ・Raw material weighing, granulation, drying, mixing, and tablet compression are all performed in environments with controlled cleanliness levels.

- ・Tablet identification can be applied not only by embossing but also by printing.

- ・High-precision cameras are used for tablet inspection to prevent foreign matter contamination.

- ・We support a variety of packaging formats, from PTP sheets to bulk filling.

![]()

Production capacity of KENEI Pharmaceutical

The Matsusaka Plant is equipped with one of the largest facilities in Japan for producing high-concentration alcohol disinfectants.

It features blending equipment that ranges from 1,000 L to a maximum of 8,000 L, enabling flexible production that can accommodate both small and large-scale quantities.

We can fill containers ranging from 15 mL to 18 L with closures including flat caps and pump caps.

Regarding bottle shapes, we have production lines that can handle sizes ranging from 60 mL to 1,000 mL, provided the bottles are self-standing.

*The term “line” does not refer to length but to a set of equipment arranged for production—for example, the area equipped for purified water production is referred to as a “line.”

QualityReliability Assurance and Quality

To provide high-quality, safe, and reliable products that meet customer expectations, we conduct strict quality control throughout the entire process—starting with the receipt of raw materials and packaging materials, and extending to intermediate product and final product testing, all the way through to shipment.

Raw material testing

Raw material testing

- Raw material testing

-

Conducted in accordance with official standards such as the Japanese Pharmacopoeia, Japanese Standards for Non-Pharmacopoeial Crude Drugs, Pharmaceutical Additive Standards, Quasi-Drug Ingredient Standards, and Food Additive Standards.

Material acceptance testing

Material acceptance testing

- Material acceptance testing

-

We verify that ordered materials meet specifications to prevent the production of incorrect products.

Intermediate product testing

Intermediate product testing

- Intermediate product testing

-

Includes physicochemical testing and microbiological testing.

Product testing

Product testing

- Product testing

-

Includes appearance inspection, physicochemical testing, sterility testing, and microbiological testing.

Stability testing

Stability testing

- Stability testing

-

We measure factors such as content and pH to ensure product quality and shelf life.

Quality assurance

We conduct manufacturing and quality assurance in compliance with GMP at our pharmaceutical production facilities based on quality manuals, manufacturing procedures, and quality control procedures.

- Supplier management

- High-quality raw materials are the foundation of product quality. We manage and evaluate material suppliers.

- Document control

- We ensure that production follows standardized methods by managing prescribed work procedures.

- Annual review

- We strive for continuous quality improvement by conducting yearly reviews of CAPA effectiveness, OOS validity, quality-related data, and audit results from regulatory authorities.