Semi-solid formulations

Semi-solid formulations

- ・We manufacture creams (W/O and O/W types), emulsions (O/W type), and high-viscosity lotions with enhanced thickness.

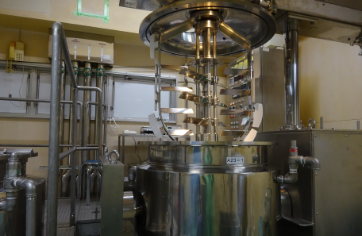

- ・In addition to the standard AGI HOMO MIXER (a standard agitator-type vacuum emulsifier), we are also equipped with the CLEARSTAR emulsifier. The CLEARSTAR offers superior micronization performance and is suitable for formulations that require mixing and dispersion with high shear force.

- ・We can handle production batches of up to 2,000 kg, meeting the needs of large-scale manufacturing.

- ・A wide variety of packaging types are supported, including jars, bottles, mist spray pumps, polyethylene tubes, and aluminum tubes.

Production flow

●High-viscosity lotion

Dissolution and blending

Liquid ingredients (such as water and glycerin) and solid ingredients (such as active components and preservatives) are added to a tank and stirred with a propeller mixer while heating as needed to dissolve and blend the materials.

Thickening

A thickening agent (e.g., carbomer, xanthan gum) is added to the solution, allowing it to swell and disperse.

Mixing and filtration

After achieving a uniform formulation through propeller mixing, the finished product is filtered and transferred to a storage tank.

Filling and packaging

The solution is filled into various containers using a filling machine, then capped or tube-sealed, and finally packed into cartons.

※For bottle-type packaging, we perform torque testing to ensure that the cap opening force meets specifications. For tube-type packaging, we conduct sampling checks to verify no ruptures occur under specified pressure, preventing leakage and other defects.

●Creams and emulsions

Dissolution and blending

Water-phase and oil-phase ingredients are separately heated and stirred in dissolution tanks to prepare the respective solutions.

Emulsification

Both solutions are transferred to a vacuum emulsifier, where they are emulsified through high-speed stirring while being heated.

Cooling, blending, and filtration

The emulsified product is cooled to a specified temperature and then paddle-stirred to ensure uniformity. Once complete, the formulation is filtered and transferred to a storage tank.

Filling and packaging

The product is filled into various containers using a filling machine, then capped or tube-sealed, and finally packed into cartons.

※For bottle-type packaging, we perform torque testing to ensure that the cap opening force meets specifications. For tube-type packaging, we conduct sampling checks to verify no ruptures occur under specified pressure, preventing leakage and other defects.

Liquid formulations

- ・We are capable of manufacturing a wide range of products, from pharmaceuticals to food additives, with a focus on alcohol-based disinfectants. Our products meet the diverse needs of medical institutions, educational facilities, offices, and households.

- ・We offer comprehensive support from planning to mass production (ODM), with capabilities ranging from small-lot to large-scale manufacturing.

![]()

Powder formulations

- ・Raw material weighing, granulation, drying, and mixing are all performed in environments with controlled cleanliness levels.

- ・We can accommodate a wide range of packaging formats, from unit-dose packages to bulk containers.

- ・Our proprietary technologies enable the development of formulations that are easy to take.

![]()

Solid formulations

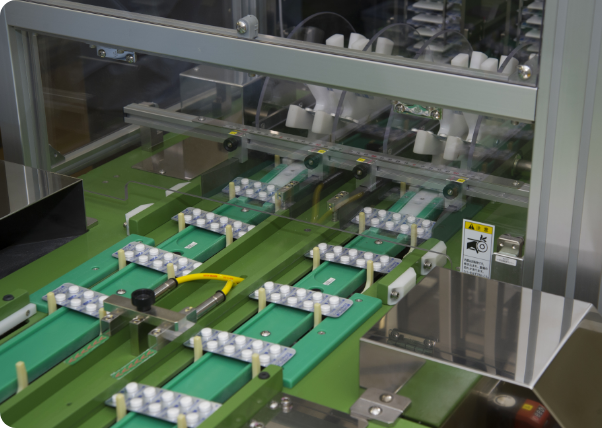

- ・Raw material weighing, granulation, drying, mixing, and tablet compression are all performed in environments with controlled cleanliness levels.

- ・Tablet identification can be applied not only by embossing but also by printing.

- ・High-precision cameras are used for tablet inspection to prevent foreign matter contamination.

- ・We support a variety of packaging formats, from PTP sheets to bulk filling.

![]()